ECOTIP: THE BEST CHOICE FOR SIDE-GATED TECHNICAL MATERIALS!

EcoTip - An optimally coordinated concept between hot runner and injection mould is the basis for excellent mould solutions that ensure productivity and durability. Our customers in the medical and pharmaceutical sectors attach great importance to this!

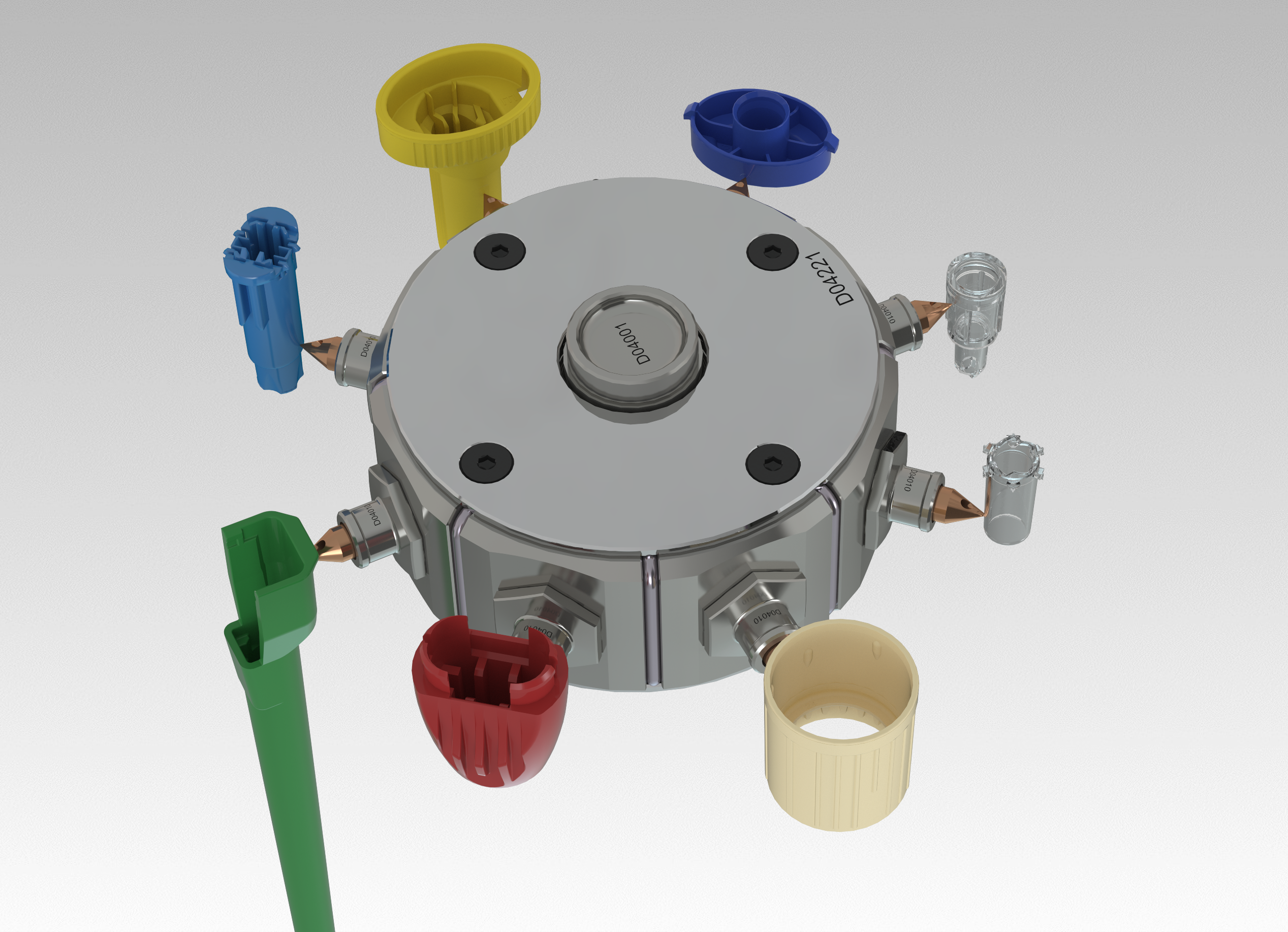

In addition to the proven KEBO star nozzle systems, the product range has been expanded for lateral full hot runners: The EcoTip nozzle makes it possible to process polyolefins (PP and PE) as well as heat-sensitive engineering plastics (PP, PE, POM, PMMA, PC, ABS, PBT).

The particularly good insulation in the nozzle body ensures minimal temperature deviation between the individual nozzle tips. Special features of the EcoTip system: a) lateral gating without separation at the sprue point and b) easy assembly/disassembly of the complete, plug-in cluster, which significantly reduces service times. The EcoTip cluster is also available in the very compact 2-, 4-, 6- or 8-nozzle version, which ensures precise, uniform melt distribution into all cavities. Challenge us with your task!

KEBO PILOT MOULDS – INSERTS AND MATERIAL TESTS

So that we can respond promptly to customer requests, material tests, further developments and rapid sample production requirements, KEBO AG uses four in-house sample moulds. As only inserts need to be manufactured in existing mould bases, the total project time frame is reduced to a minimum.

Material tests, design optimisation, gate quality, functionality of assembly parts, dimensional accuracy, steel dimensions for subsequent production moulds and the shortening of validation phases represent a crucial cost advantage for our customers.

You want to find out what our EcoTip system can do for your requirement? We are at your disposal for an initial consultation.