SAFETY FIRST FOR MOULD MOVEMENTS!

Mould movements have never been safer than in our unique LIFT & STRIP concept. Thanks to an innovative, multi-stage internal gearbox, the necessary movement sequences are designed specifically for the moulded part and thus integrated into the mould concept. The mechanics make it impossible for the moving parts to accidentally collide with each other. Safety first! In addition, the innovative mould concept only requires the central machine ejector as a drive unit.

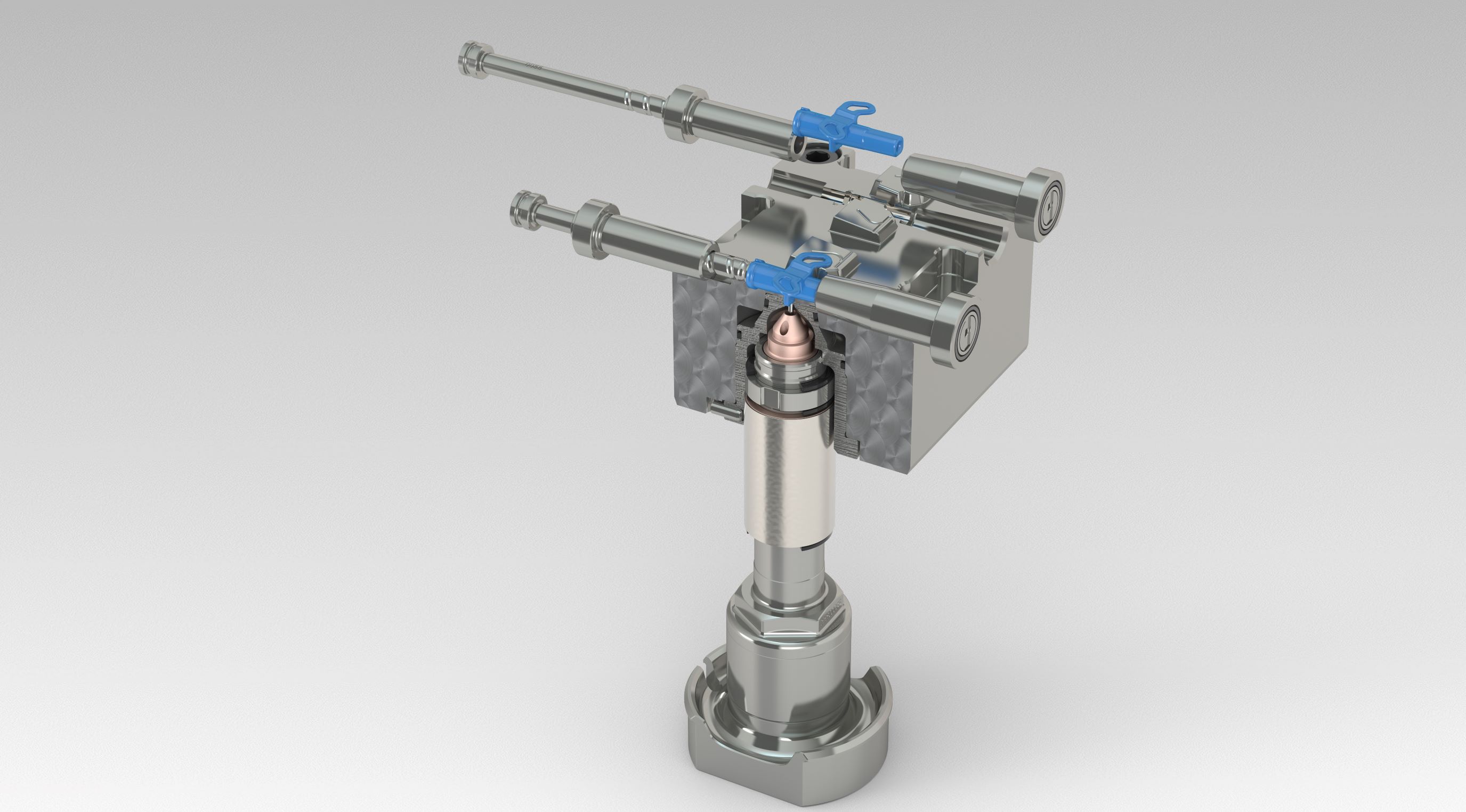

The first-class gate quality required for medical applications is ensured by KEBO's own valve gate system. The smallest needles and nozzles produced in-house allow heat-sensitive technical plastics (e.g. POM, PMMA, PC, ABS, PBT) to be processed with (gate) precision and process reliability. Challenge us with your task!

KEBO PILOT MOULDS – INSERTS AND MATERIAL TESTS

So that we can respond promptly to customer requests, material tests, further developments and rapid sample production requirements, KEBO AG uses four in-house sample moulds. As only inserts need to be manufactured in existing mould bases, the total project time frame is reduced to a minimum.

Material tests, design optimisation, gate quality, functionality of assembly parts, dimensional accuracy, steel dimensions for subsequent production moulds and the shortening of validation phases represent a crucial cost advantage for our customers.

You want to find out what our Lift & Strip system can do for your requirement? We are at your disposal for an initial consultation.