Innovative tools to meet the challenge in the pharmaceutical sector

The design and construction of tools for the pharmaceutical industry have been among KEBO AG’s core competencies right from the start. This means that the company has developed in-depth knowledge of the field. It forms the basis for smart solutions for hard factors such as functionality, product integrity and accuracy of dosing. Even with softer criteria such as design aspects or overall look and feel, it provides for very interesting approaches.

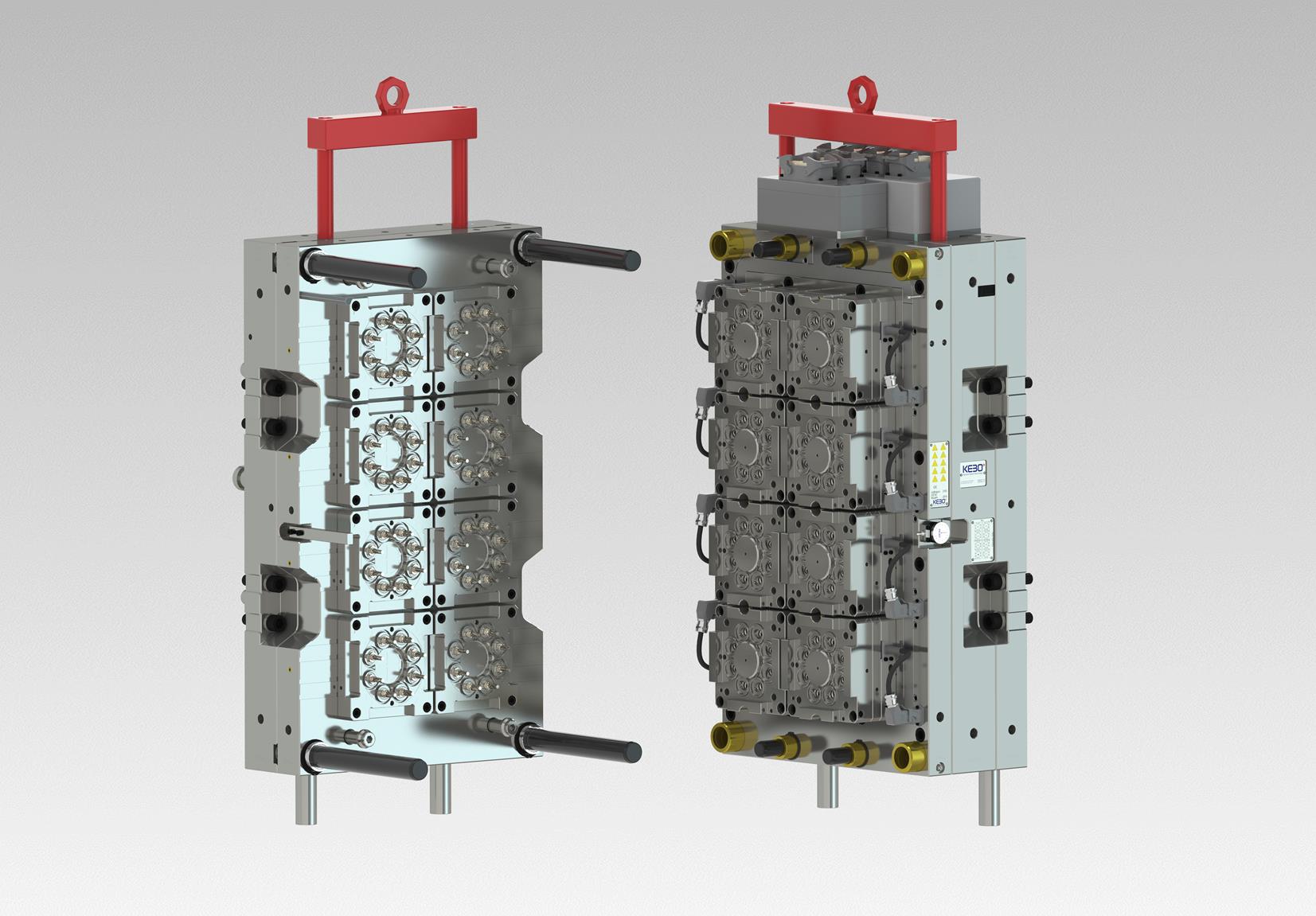

The profitability and quality of our products are based on technologies that we have used and continually developed over many years. At the core of our work is our full hot runner system with up to eight injection points per cluster, stack moulds for maximum space utilisation and extremely high surface quality, which passes even the most critical inspection.

Our moulds are consistently designed to have long lifetimes. Our high precision produces tools that impress our customers, including from a profitability point of view. Wear and tear appear long after the periods defined in the specifications for comparable products. The wall thicknesses can be reduced to a minimum, which means material savings over the long term. The generous maintenance intervals ensure that production can be continued without faults over long periods.

Typical products include:

• Filters

• Reaction and analysis vessels

• Laboratory items

• Parts for pump bodies

• Spray heads

• Tablet tubes

Standards lead to reliability and reduced risks

In the last years we have established clearly defined standards in Medical & Pharma Applications. For many of these pharma mouldings we rely on well-proven design standards which permit us, thanks to optimally laid out hotrunner systems, to achieve the maximum productivity of your plant and equipment.

Whether 16, 32 or up to 144 cavities – in one plane or on two tiers: A maximum quality of your plastic parts and especially also of the gate, top surface quality and fast cycles are the result of a perfect interaction between hotrunner and mould.

Ever since the nineteen-eighties, KEBO AG has been using its own fully-heated hotrunner technique for Medical & Pharma Applications, also where stack-moulds are concerned. The service-friendly and modular design of the cluster principle allows to take optimal advantage of the space available in your injection moulding machine, thereby optimizing the economic efficiency of your entire production system.

KEBO AG has four own test moulds (of pre-series execution), two of which with fully heated hotrunners for side-gating. Seeing that only the inserts for existing impressions need to be made, weak spots can be detected and dealt with at an early stage and quickly.

We are familiar and experienced with different concepts for the lying arrangement „lift & strip“, side-gating with unscrewing or the use of electric servo-motors for unscrewing or gate-pin actuation.